Archive

Top 15 producers of c-Si and thin film solar PV modules, and outlook 2011

I am extremely grateful to Stefan de Haan, senior analyst, Photovoltaics, iSuppli Corp., for sharing with me the top 15 global producers of c-Si and thin film solar photovoltaic (PV) modules, respectively during Q3 2010.

First, the top 15 global crystalline module producers (see Fig. 1) — who are the standout performers and why?

He said: “It is still the Chinese integrated suppliers, above all Trina and Yingli. They benefit from a highly competitive cost structure. However, this need not be the most successful business model in future. With increasing cell and module efficiencies, and an increasing need for full automization, European and Japanese companies may gain ground again.”

Now, on to the top 15 global thin film module producers (see Fig. 2)– who are the standout performers here!

de Haan added: “Still, it is First Solar, the company with lowest production cost in the industry and the biggest module producer. CIGS is upcoming, in particular. Solar Frontier also has to be watched.”

Global PV installations to grow significantly in 2011

It is said that global PV installation will likely witness moderate growth in 2011, and that, concerns of oversupply remain. de Haan agrees only partly.

He said: “Global PV installations will again grow significantly in 2011 (2010: 16 GW and 2011: 22.2 GW). Oversupply will not be dramatic in 2011, but in 2012 and 2013.”

Further, if the pressure from decreasing solar cell price continues to increase, will solar cell makers be forced to reduce prices of wafers and poly-Si to reflect costs? According to Stefan de Haan, prices will drop across the entire solar value chain in 2011! Read more…

Dramatic price forecast to reshape PV industry: iSuppli

I was very fortunate to attend a webinar on solar PV a couple of days back, thanks to iSuppli, USA. The webinar looked at:

* Polysilicon — what is going on in the market?

* Cells and modules — where will the prices go?

Dr. Henning Wicht, senior director and principal analyst, iSuppli, made it clear that the intention was to show what’s coming out of primary industry research.

Dr. Henning Wicht, senior director and principal analyst, iSuppli, made it clear that the intention was to show what’s coming out of primary industry research.

He said: “We believe that solar is a fantastic market. It has been growing over the last four years by revenue. It will continue to grow! There are not many industries with a growth path like that! However, in last the 18 months, the supply has been disconnected from demand.”

This is exactly the point iSuppli addressed in its webinar. Dr. Wicht was accompanied by Stefan de Haan, senior analyst, photovoltaics, iSuppli.

iSuppli’s recent findings are:

* Severe supply chain imbalances exist at polysilicon/wafer and cell/module levels.

* Short term polysilicon and module prices will decrease significantly.

Polysilicon: What’s going on with supply and pricing?

If you looked at the global solar PV industry, many plants are under construction, and there are huge capacity expansion plans. There has been a dramatic decrease in production. In 2008, iSuppli estimated total production of solar PV at 60,000 metric tons. In 2009, about 100,000 metric tons will be produced!

What are the reasons for this supply situation? In 2005-06, the high margins of this industry attracted several newcomers. The cycle time to ramp up a polysilicon plant is 24-36 months, and including another 12 months to get finance, it takes about four years.

He said: “The decisions taken in year 2005-06 are coming to the market now. This is also why we see the big ramp in 2009-10. This is also the reason why the industry will have big difficulties to react on a short term notice. The polysilicon industry is a big super tanker, which has difficulties to maneuver on short term.”

Looking at the demand side of things, iSuppli showed a graph where the two curves — polysilicon supply and polysilicon demand meet, or rather cross, in early 2010. From that point on, the supply line passes the demand line. “That means, from that time onward, we definitely see prices for polysilicon decreasing,” he said.

What will happen in 2009?

The key point to note is that the ramping rates of polysilicon and solar cells are completely different! The ramping rate of polysilicon is much steeper, than on the cell side. Polysilicon is more than doubling, while the cell industry is growing at 34 percent.

According to Dr. Wicht, the gap between demand and supply is already shrinking fast in 2009, which will lead to a price decrease in 2009.

Coming to prices, the polysilicon market boasts two kinds of prices — long term and spot market. According to Dr. Wicht, the long term prices are already decreasing from around $100/kg in 2008, and it is expected to be around $80/kg in 2009.

On the other hand, the spot market price peaked in 2008 at around $400/kg. Now, it has already dropped. It will continue to drop, far beyond today’s long term contract price, which will then, from 2010 onward, make up another round of discussion. This is because companies might tend to get out of their long term contracts to secure their silicon on the spot!

Summarizing, he said that polysilicon production will increase heavily. Next, supply will pass demand from 2010 onward, and then the industry will enter the oversupply situation for the next three to four years. The polysilicon industry will also react. In fact, iSuppli anticipates a recent announcement from a solar PV company to expand production capacity would be the last for quite a while!

What about projects on the way? These projects have to come on to the market and many of those will! This is precisely the reason why the industry will see silicon passing solar cells in capacity over the next few years.

Stefan de Haan added that the output of the PV modules industry will grow. The total module prod will likely grow to 11GW this year and to 20GW in 2012. Thin film modules will continuously gain market share and it probably account for 1/3rd of the total market by 2012. Production of crystalline cells will run in parallel. It is likely to reach 9GW for 2009 and 18GW for 2012.

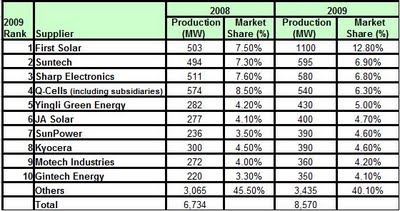

Commenting on the competitive landscape, he added that many new players would be entering production in 2009, especially in the thin film business. “However, the current leaders — QCells, Suntech and First Solar — will increase their edge over the competition in terms of absolute production volumes,” he said.

In general, it is a good thing that the industry is growing and that all of this capacity is coming online. However, this raises the question: can demand can keep up with the supply?

According to iSuppli, in 2009, the installation market will be flattening. In the sense, iSuppli projects that 4.2GW will be installed this year, or about 10 percent growth. However, this growth is much smaller in comparison to the previous years. Some of the reasons for slower growth in 2009 include changes in sustained feed-in tariffs and the global economic slowdown.

Hann added, “In H2-2010, module demand will probably return to the previous growth rates, of more than 20 percent per year.”

Combining demand and supply, there is a massive oversupply of modules that has already been building up since early 2008. Back in 2008, this did not impact on the module prices as there was short term heavy demand from countries like Germany and Spain, from project developers and installation companies, etc. So, this was not noticeable earlier. However, in 2009, the oversupply situation is quite serious!

As a consequence, many suppliers will not be able to react to this situation in the short term. They will still need to run their factories to try and generate some revenue and satisfy the industry. Many had bet on some strong demand coming from USA and also China.

This year, the module prices will decline. Consequently, the declining prices will also create some additional demand. However, for the next two years, this fundamental oversupply situation will not change.

How far will prices drop?

So, what are the message for 2009? First, crystalline module prices will drop to about $2.50 per watt, and second, cost is going to be the differentiating factor! This was a point emphasized strongly by the iSuppli analysts.

Further, how should companies manage this situation, where supply is disconnected by demand? According to Dr. Wicht, there is 11.1GW of module supply vs. 4.2GW of installations. “We do not see that the demand is elastic and that everything will be good after the end of 2009. The gap is too large between demand and supply, and will last till end of 2010.”

Installation capacity will surely become a bottleneck. There will be falling prices for silicon, as well as solar cells and modules. Also, the demand is not that elastic enough to absorb all modules produced.

Therefore, given this situation, what are the options for success, rather, what are the ideas to re-orient the solar PV business?

The first option could be to shut down 50 percent of production till price recovers. However, this is not a realistic option. Another could be to put expansion plans on hold. Yet another option for producers would be to become the best in class in production cost, an option, which is excellent, but difficult!

Probably, the best option would be for mak

ers to integrate downstream. This includes new demand simulation in established markets as well as developing new markets.

Dr. Wicht said: “Anticipating bottlenecks are key for solar. The next bottlenecks are the bureaucracy and installation capacity. The production capacity would not be influential. Production cost and downstream integration are key.” He advised solar PV producers to monitor their PV market demand and supply situation regularly.