Archive

Embedded Vision Alliance (EVA) is born!

The Embedded Vision Alliance is born! Over 15 leading technology companies, including some really big names in semiconductors, have come together in Oakland, USA, to ‘ speed the adoption of computer vision capabilities in electronic products’.

BDTI, Xilinx, and IMS Research initiated the Embedded Vision Alliance (EVA) and are being joined by Analog Devices, Apical, Avnet Electronics Marketing, CEVA, CogniVue, Freescale, National Instruments, NVIDIA, Texas Instruments, Tokyo Electron Device, MathWorks, Ximea, and XMOS as founding members.

According to a release, the ability of machines to see and understand their environments—what we call “embedded vision”—promises to transform the electronics industry with products that are more intelligent and aware of their environments, and to create significant new markets for electronic equipment and components.

This new consortium, called the Embedded Vision Alliance, will enable the proliferation of embedded vision technology by providing design engineers with information, practical know-how, and industry standards.

While the participants in this Alliance need to be congratulated for their foresight, one wonders what took them so long!

Also, I do not see any Indian company in the list, although, the embedded systems and software industry here is quite large. Names, such as Ittiam, Tata Elxsi, etc., should be part of this Alliance, but they are absent, as of now!

Now, the EVA’s commitment is to vision technology and enabling customers to develop the industry’s most innovative hardware, development tools and software to make vision application development easier. One of the founders has commented that embedded vision will be used on automobiles to prevent accidents and to security cameras to prevent crimes. Should this happen, embedded vision will surely proliferate across a multitude of markets! We are all waiting really patiently for such days!

No real fun being at DAC or ESC! Seriously!!

The 48th Design Automation Conference (DAC) kicks off in about a month’s time in San Diego, California, USA. I have been flooded with invites. There’s also an Embedded Systems Conference starting tomorrow, in San Jose. However, I will give both of the events a miss! Why? Simply because of one fact! The EDA industry has stopped surprising me! And, so has the embedded systems industry!!

I an very well aware of the changing and ‘challenging’ trends in the global semiconductor industry. I should also add that I do have at least some knowledge of the global EDA industry in 2010 and its expectations for 2011.

I am aware of the fact that product lifecycle management involves reducing the time-to-market cycles for new product introduction. Industry folks have, time and again, apprised me of the fact that there is a need to bridge the gap between software and hardware – and growing the IT and VLSI industries.

Cadence, for instance, will share a new technology that addresses some of the toughest challenges detailed in the EDA360 vision at ESC 2011. For how long will the challenges be met? Synopsys seems to be raking in the dollars, year after year. Mentor, despite its ‘current issues’, has been doing fairly well. So, what’s new over here?

In embedded, it is very well known globally, that India is an emerging leader. Otherwise, there is hardly any electronics or semiconductor related manufacturing happening in India, despite the best efforts of the ISA.

So, why isn’t all of this being viewed as industry growth? Maybe, you have all the answers! I will only try to sound more optimistic, without creating additional pain!

Almost all of the new techniques and technologies to be announced at either conference, will or already have made their way to India. Or, the companies using them are not allowed to speak about them, at best!

Top 10 Indian embedded companies!

It has been over two years since I wrote the piece — Top 10 embedded companies in India! It has been the most read, and by far, the most commented. Now, it is time to do a review, or, more suitably, a recap!

First, who are the top 10 (Indian) embedded systems and software companies in India? My list, in no particular order, would read something like this:

1. Ittiam

2. Sasken

3. CMC

4. C-DAC

5. L&T EmSyS

6. ProcSys

7. eInfochips

8. Mistral

9. iWave Systems/Global Edge

10. Vayavya Labs

There are several firms in Pune and Hyderabad, who probably deserve a name. There may be some folks may not agree with this list, but I would go with these, for now. The next change could be two years down the road!

Some may even question the presence of CMC and C-DAC in this list. However, CMC has well over 30+ years of extensive experience in providing consulting, design and development services and testing services in real-time systems.

C-DAC has capabilities in high-performance computing as well as grid computing. It also has unit focusing on professional electronics, including embedded and VLSI products.

Ittiam and Sasken remain in the top 5 category. ProcSys is a new entrant, besides iWave, Global Edge and Vayavya Labs.

Now, may I know if you have any doubts, as well as moves, additions and/or changes (MAC)? 😉

Women power, RVCE rule at first annual Karnataka VLSI and embedded systems awards

It is always a pleasure to witness women power in technology! More especially, in India!! To my pleasant surprise, and am sure, of many others present, women power was aplenty at the first annual Karnataka VLSI and Embedded Systems Awards distribution ceremony held today at the RV-VLSI Design Center, Bangalore.

First, the winners! Congratulations to each one of them on their achievement!

VLSI category

Winner: Suraj H, Vinay R, Vinaya Ajjampura and Vasudev Pai M, RVCE, E&C.

Title: Design and verification of 16-bit pipelined microcontroller.

Runner-up: Deepika, Deepthi MN, Divya V Nayak, RVCE, Telecom — an all-women team!

Title: Design and verification of stand-alone DMA controller.

Embedded category

Winner: Praseed Chandriki, Prashant Bhat, Anup Reddy, Manoranjan S, RVCE, E&C.

Title: Implementtion of media transport in VoIP and performance analysis through measurement of QoS.

Runner-up: Ashwini HV, Sayak Bhowmick, Shruthi BR, Shruti S. Rao, Global Academy of Technology, E&C.

Title: DARAM driver for VoIP router.

It was announced that Mentor Graphics, along with STMicroelectronics, will be sponsoring next year’s awards.

This year’s contest was initiated by RV-VLSI in close association with VTU, and sponsored by Mentor Graphics. Dr. Walden C. Rhines, CEO and chairman, Mentor Graphics, graced the occassion. Dr. V.S. Acharya, the Honorable minister for Higher Education, Planning and Statistics, Government of Karnataka, who could not make it to the event owing to pressing official work, had his message read out.

Other digitaries present on the occasion included Hanns Windele, VP Mentor Graphics (Europe & India), Ian Burgess, Higher Education Program, Mentor Graphics, CV Hayagriv, Trustee, Rashtreeya Sikshana Samiti Trust, and chairman, governing council, RV-VLSI Design Center, AVS Murthy, honarary secretary, Rashtreeya Sikshana Samiti Trust, and Dr. MK Panduranga Setty, president, Rashtreeya Sikshana Samiti Trust (RSST).

RV-VLSI can tape-out multi-billion transistor chip today!

Venkatesh Prasad, CEO, RV-VLSI Design Center, said it was his interaction with a visionary like Dr. MK Panduranga Setty, and the support of the board of trustees of RSST that made it easy for him to transition out of the industry and start RV-VLSI. The vision of RV-VLSI is to create a steady stream of well trained professionals with a low TTP (time to be productive). To achieve a low TTP, it had to do things different from a traditional academic institution.

That differentiation started with the name, RV-VLSI Design Center itself, rather than RVDI. Next, the institute procured a Sun data center to meets its complex needs. Next, it gained access to foundry technology from Tower Semiconductor and EDA software from Mentor Graphics. Prasad added, ‘RV-VLSI has the infrastructure to design and tape-out a multi-billion transistor chip today.” Read more…

Is the Indian semicon industry losing the plot?

Every time I see a new electronics or related segment being talked about in India — be it medical electronics/healthcare, RFID and smart cards, or for that matter, telecom, why do I get this feeling that the Indian semicon industry is slowly losing the plot? One hopes not!

The Indian technology industry is talking about practically everything, except semiconductors. Yes, I know we have a great pool of designers who work in the MNCs. Also, there are plenty of Indian design services companies doing excellent work (for others?). India’s strength in embedded is folk lore. Despite all of this, we are, where we were a few years ago!

Back in 2007, I’d done a story on how there were very remote chances of having a fab in India. Back then, some industry folks expressed optimism that the fab story was not dead! However, that story is well and truly dead and buried, as of now! Today, no one wants to talk about a fab — fine, then!

Let’s do a reality check on India’s semiconductor score-card!

So far, India has not even managed to have a small foundry, forget about having a fab! Nor has the Indian industry managed to develop, nurture and build many (or any?) fabless companies of note. Can you tell me how many Indian fabless semicon companies have come up in the past five years? How many globally known Indian semicon product start-ups are there in our country for that matter? Okay, how many Indian semicon product start-ups are there in our country?

For that matter, how many ATMP units have come up in India? I do recall some industry folks mention in the past that there will be some ATMP units happening. Where are they? Okay, who, in India, is even trying to develop IP libraries?

Even if there is some success in building electronic product companes — that is and will be limited success! Neither is there any evidence of cutting-edge R&D being done in India. Please do not mix this up with the work being done by the Indian arms of the various MNCs.

Why, I don’t even think that the industry-academia partnership has developed substantially, leave alone mature!

If medical electronics, or some other related area, were to go on and succeed in the near future, it would be counted as a success for the Indian electronics industry, and not for the Indian semicon industry! Even if this did happen and it was counted as a ‘semicon success, can anyone make a guess as to how many of the chips going into such devices would be actually made in India – by Indian firms?

I had mentioned back in Feb. 2009 that “Can the Indian semicon industry dream big? (And even buy Qimonda?)! To refresh your memory, there was a large 300mm fab up for sale in Dresden, Germany. Well, even that never happened, or well, the Indian industry did not think it to be of much importance!

Back in August 2009, there was news about Texas Instruments (TI) placing a bid of $172.5 million for buying Qimonda’s 300mm production tools from its closed DRAM fab. While this highlighted TI’s focus on building the world’s first 300mm analog fab, I can’t stop wondering: what would have happened had an Indian investor actually bought Qimonda’s fab!

Perhaps, it would be better for the Indian semicon industry to stick to its globally known strengths of providing excellent semiconductor design services and embedded design services. At least, there will be clear direction in these areas.

Of course, there exist huge opportunities in all of the areas (or gaps) that I’ve touched upon.

7 principles for bridging hardware and firmware divide: Gary Stringham

Embedded designers, are you having problems with the firwarre (embedded software) running on your hardware? For instance, do you wish to reduce chip respins? Or, would you like to improve on the hardware and firmware integration?

These and several related queries were answered by Gary Stringham, founder and president of Gary Stringham and Associates, LLC, USA, in an interactive session organized by the Bangalore Chamber of Industry and Commerce (BCIC), in co-operation with the US Commercial Service, Bangalore, and in association with the India Semiconductor Association (ISA).

Here are the seven principles that Stringham highlighted during his session. These principles should be of great interest to designers of embedded systems in India, and elsewhere. These are:

1. Collaborate on design.

I will add some more stuff for each one of these points, time permitting.

Round-up 2009: Best of EDA, embedded systems and software, design trends

Friends, the next installment in this series on the round-up of 2009 lists my top posts across three specific fields that are very important within the semiconductor industry — electronic design automation (EDA), embedded systems and software, and some design trends. Here you go!

EDA

Synopsys on Discovery 2009, VCS2009 and CustomSIM

State of global semicon industry: Hanns Windele, Mentor

New routing tool likely to cover upcoming MCMM challenges: Hanns Windele, Mentor

Cadence’s focus — systems, low power, enterprise verification, mixed signal and advanced nodes

Zebu-Server — Enterprise-type emulator from EVE

State of the global EDA industry: Dr. Pradip Dutta, Synopsys

Mentor’s Wally Rhines on global EDA industry and challenges

Mentor’s Wally Rhines on EDA industry — II

Cadence’s Lip-Bu Tan on global semicon, EDA and Indian semicon industry

Indian EDA thought leaders can exploit opportunities from tech disruption!

EMBEDDED SYSTEMS & SOFTWARE

Top 10 embedded companies in India — By the way, this happens to be the most read article of the year!

NI LabView solves embedded and multicore problems!

Intel’s retail POS kiosk provides unique shopping experience

ISA Vision Summit 2009: Growing influence of embedded software on hardware world

MCUs are now shaping the embedded world!

Embedded electronics: Trends and opportunities in India!

Growth drivers for embedded electronics in India

DESIGN TRENDS

Microcontrollers unplugged! How to choose an MCU

Xilinx rolls out ISE Design Suite 11 for targeted design platforms!

TI’s 14-bit ADC unites speed and efficiency

ST/Freescale intro 32-bit MCUs for safety critical applications

Again, I am certain to have missed out some posts that you may have liked. If yes, please do point out. Also, it is not possible for me to select the top 10 articles for the year. If anyone of you can, I’d be very delighted.

My best wishes to you, your families and loved ones for a happy and prosperous 2010.

P.S.: The next two round-ups will be on solar photovoltaics and semiconductors. These will be added tomorrow, before I disappear for the year! 😉

Growth drivers for embedded electronics in India

The strength of India’s embedded systems and software industry is well known globally. Naturally, interest is extremely high in this area.

Keeping that in mind, the India Semiconductor Association (ISA), recently organized a conference on “Embedded Electronics: Trends and opportunities in India”, during the BangaloreIT.biz event.

Speaking on the global electronics systems design and manufacturing ecosystem, BV Naidu, chairman, ISA, estimated the global electronics industry at $1.75 trillion for 2009, and projected to reach $2 trillion in 2014. The annual growth rate has been 3 percent for 2004-09.

India lags behind in (electronics) numbers!

India’s story is starkly revealed in its numbers. While the electronics industry is the key to national growth, India is extremely small in this segment. Taking telecom/electronics hardware production as a share of GDP, China has a GDP share of 12.7 percent, while India only has 1.7 percent share.

Even smaller countries, such as Korea — 15.1 percent, Taiwan — 15.5 percent, and Israel — 23.6 percent, respectively, have much higher GDPs. The share of USA is 5.4 percent, Japan — 4.5 percent, and Germany — 8.3 percent, respectively.

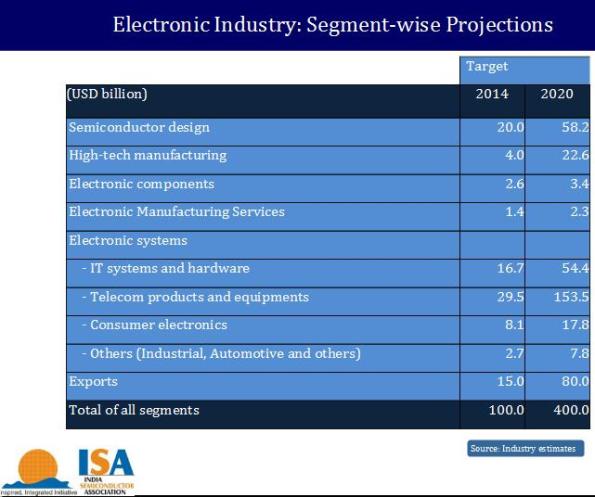

India’s domestic production, excluding imports, is $10.8 billion during 2009. Consumption reached $45 billion in FY09 and the demand is likely to reach $125 billion in FY 2014. The expected domestic demand will likely grow 22 percent from 2009-2020, reaching $400 billion by 2020. Exports reached $4.4 billion in FY09, and it is likely to reach $15 billion in FY14 and $80 billion in FY20, growing at 31 percent.

The trade imbalance is projected to increase to $323 billion by 2020 as the imports of electronic products are likely to increase to 16 percent of the GDP. As a result, it is important for some Indian companies to play a major role.

It has the potential to leapfrog!

There exists a tremendous potential for India to leapfrog technologies and lead. Potential exists in several areas such as wireless, smart meters (AMI), LEDs, green energy/energy efficiency, affordable devices/telemedicine, digital classrooms/virtual classrooms for education, digitization in terms of electronic society/unique ID/TV, radio, etc., integrated surveillance systems, and low-cost zero emission cars.

Touching on the VLSI/electronics ecosystem, Bangalore itself is home to over 90 companies in VLSI and embedded. However, most of these are arms of MNCs. High-tech manufacturing does not exist, as yet. However, the solar PV industry has been attractive recently, and high-tech manufacturing is likely to grow there. The silicon fab, however, may take some more time.

Within the Indian electronic system design industry, there are companies such as Ittiam, SemIndia, etc., who focus on made in India and made for India. Naidu called upon the government to encourage the domestic manufacturing and systems companies.

In this respect, the electronic components and accessories ecosystem industry is currently moderate. It used to be 15 percent and has now grown to 35 percent. That means, 35 percent of the costs of production can be sourced and managed using components from India.

India has managed to attract some EMS companies, especially to Sriperumbudur, an industrial town in the Kanchipuram district, Tamil Nadu. However, low end products are being developed, or rather, work that is at the low end of the value chain is being done. That needs to change! Here, embedded software can play a key role.

Segment-wise projections for the Indian electronics industry. Source: India Semiconductor Association (ISA)

“Our local markets should provide opportunities for the local companies. Access to global markets will help us grow,” he added. He presented segment-wise projections for the Indian electronics industry up to 2020 (see table). Read more…

MCUs are now shaping the embedded world!

As promised, here’s a discussion I had with STMicroelectronics (ST) on its new 8-bit microcontroller, the STM8S — the STM8S105 and STM8S207 MCUs for industrial and consumer applications. The discussion focused on how MCUs are now beginning to shape the embedded world.

Addressing this specific query, Patrice Hamard,8-bit Product Line Marketing Manager, STMicroelectronics, said that ST is reshaping the microcontroller with a solid offer on 8bit that has a strong overlap with STM32 in terms of feature and price. “Therefore, we are going to cover the need for embedded functions with only two architectures. Compared to the previous segmentations (8-, 16- and 32-bit), we are changing it to become 8- and 32-bit only,” he clarified.

Addressing this specific query, Patrice Hamard,8-bit Product Line Marketing Manager, STMicroelectronics, said that ST is reshaping the microcontroller with a solid offer on 8bit that has a strong overlap with STM32 in terms of feature and price. “Therefore, we are going to cover the need for embedded functions with only two architectures. Compared to the previous segmentations (8-, 16- and 32-bit), we are changing it to become 8- and 32-bit only,” he clarified.

On the STM8S, Hamard said that the key application areas addressed by the MCU are industrial and appliances in consistent with the robustness and the reliability. He said: “The STM8S family is supporting 5V as well as 3V, thereby making it ideal for the platform evolution as well as a good offer for the consumer and mass market. The cost advantage given with the fine lithography also allows us to propose this family to key customers in PC peripherals and consumer applications.”

Rich feature set an imperative in MCUs

Rich feature set is an imperative in the MCU market. How is the STM8S meeting this requirement?

According to him, the feature set is driven by the need to reduce the bill of materials (BoM). The robustness allows simple design and board layout with less filtering. The clock controller gives low noise emission figure, thereby reducing the need for shielding. The precise clock allows the suppression of the external resonator. The embedded true E²Data suppresses the need for additional E²PROM. Safe reset (no grey area) makes the reset system safer suppressing the need for external reset circuit.

The clock system, as well as the two independent watchdogs will contribute to pass safety regulations together with ST’s class B libraries. All communications peripherals are available as well — (U(S)ART, I²C, SPI, CAN, LIN), advanced 16-bit timers and timebase, fast and precise 10-bit ADC.

Finally, the 8-bit core is one of the most efficient with 20MIPS at 24MHz. Built around the 8-bit data path, the micro has 16bit registers and 32bit memory memory width.

So, how does the STM8 deliver high performance with excellent code compactness?

Hamard said that thanks to the new CISC instruction set designed in collaboration with ST’s C compiler partners, the compactness has been significantly improved. The Harvard architecture with its three-stage pipeline allows to reach up to 20MIPs @ 24MHz.

ST is offering family demonstration boards and instrument cluster reference designs as well. In fact, there are currently solutions available in ST with the STM8S/128-EVAL, as well as with third parties like raisonance with the REVA KIT. Many reference designs are complete or in progress demonstrating motor control (sensorless brushless DC motors), power management, smart card protocol, capacitive sensing, etc.

Demand for low-power MCUs

According to Hamard, the trend of low power is coming from the increase of the application base on battery in consumer and personal care, combined with a strong demand for power meters (electricity, water and gas). Energy saving is important and electronics can contribute a great deal to reduce the overall energy consumption.

“The STM8S is not specifically aiming low power applications even though the features of the family are good for many low power devices. It is in our plan to introduce later this year a dedicated family to address low voltage/low power arena,” he added.

Why 8-bit?

Considering that there are 8- vs. 16- vs. 32- bit MCUs, and also that affordable prices are perhaps the reason that the Asian region is witnessing a migration to 16-bit architectures. In this scenario, why 8-bit?

Hamard said: “Everything depends on what we consider to be “affordable” and who we are talking to. For large quantity and simple functions, affordability is between $0.20 cents to $0.50 cents. By construction, a 16-bit device cannot be as effective as an 8-bit product. We even believe that the microcontroller prices will decrease and address applications served with few discrete devices. The main reason is the consistency of architecture.

“The construction of the 32- and 16- are very similar, especially with the new generation of ARM-based products. The only reason to go from 8- to 16-bit is for performance improvement. We say that our 32-bit portfolio is already overlapping the 8-bit segment in performance and in price, leaving no room for the third core structure.

“Taking a closer look at our portfolio, you will realize that our 32-bit is also providing 16-bit instruction set, and our 8-bit is built with 16-bit register, 24-bit memory address bus, etc.”

ISA Vision Summit 2009: Growing influence of embedded software on hardware world

This session on day 1 of the recently held ISA Vision Summit had a good mix of speakers. Moderated by Anil Gupta, managing director, ARM India, the speakers included V.R. Venkatesh, Senior Vice President, Product Engineering Services, Wipro Technologies, Kishor Patil, MD & CEO, KPIT Cummins, and Raju Pudota, MD, Denali Software. This is a slightly longer blog post, so bear with me, friends.

The pic here shows Wipro’s Venkatesh making a point, watched by Raju Pudota, Amil Gupta and Kishor Patil.

The pic here shows Wipro’s Venkatesh making a point, watched by Raju Pudota, Amil Gupta and Kishor Patil.

Kicking off the panel discussion, ARM’s Anil Gupta highlighted the strength of the Indian embedded software industry. As per IDC, embedded software accounts for 81 percent of the projected share of overall revenues in 2008, at $5.98 billion. This will go up to $7.29 billion, while still accounting for 81 percent of the projected share of overall revenues in 2009. The projected share of the overall workforce in this industry segment stands at 82 percent — at 125,663 — which will be maintained during 2009, even as this figure rises to 149,978! Quite impressive!!

Incidentally, a recruiter recently requested information on the workforce numbers in the Indian semiconductor industry. I hope this partly answers your question, friend.

Gupta further added that embedded design had now entered several sectors such as automotive, aerospace and defense, consumer and home products, household appliances, industrial controls, infrastructure and construction, medical electronics, transportation and traffic management, security and telecom. In short, a bright future for this segment ensured, especially in India.

Trends in embedded design include: more demand for features, embedded is driving complexity, and prices have been generally constant/going down. As a result, all of the innovation happening has been giving new experience to the consumers.

Wipro’s V.R. Venkatesh cited the example of medical devices, which are adding functions via embedded software. He presented the case of an efficient infusion pump, which ensures that the five rights of medication safety — right person, right dose, right medicine, right time, and right way — are never violated!

Another example cited was of adding functions in mobile devices. Such mobile devices are making use more dual core chip solutions to run multimedia and MIPS intensive apps on a separate applications processor. They use open operating systems (OS) such as Symbian, Linux, etc., and also have built in sensors, such as motion sensors.

Consequently, usability is now becoming the focus, rather than pure user interface of the mobile. On the impact of software complexity, he said that OSs and middleware are now becoming more complex to enable quicker and easy to develop mobile applications, and also develop complex mobile application with the right API support. He also cited new advances in automotive telematics and navigation. These are implemented through complex software and demanding more hardware features.

Challenges in developing embedded software

However, increasing embedded software has also brought its own challenges. Today, the share of software is ~50 percent of the total cost of development.

Some of the challenges while developing embedded software include multiple regulations; split personality: display (local and remote), compute and communicate; UI; low-power design, application specific accelerators; wireless as de facto connectivity; integrated sensors and geospatiality for enhanced applications; built for untrusted environments (security, virtualization); and integration with service providers and enterprise systems.

Hardware and software in an embedded system are complimentary to each other. Software (middleware and applications) should be used as a ‘Differentiator’ to add more winning features to any new product, he added. There is a need for a platform approach for embedded software development to enable scaling of features and usage across applications. Finally, developers need to keep the cost vs. functions vs. efficiency tradeoff in mind.

Embedded systems landscape trends

KPIT Cummins’ Kishor Patil touched upon the growing need of convergence for hardware and software. According to him, the key driving forces are:

* Low cost and high performance;

* Low power and green;

* Maximum storage and least area/cost;

* Development: Faster TAT (turnaround time);

* Mechanical centric => electronics centric; and

* High value and low cost.

Trends in hardware include silicon shrink at 0.7x, technology challenges at 45nm and below, and business challenges — high volumes for amortizing high mask costs.

Commenting on the embedded systems landscape: market trends and implications, he cited these to be: electronics and applications emerging as distinctive factors; increased electronics in automobiles (~100 MCUs/ECUs per car); silicon shrinkage reaching its limit w.r.t. geometry and costs; and enhancing system performance with the same hardware.

Content growth has been quite notable in automotive electronics. According to Patil, in 2000, an average automobile had 1 million lines of code, 20 ECUs, electronics worth $400, and software constituted 2 percent of the cost of the car. By 2010, an average car will have 100 million lines of code, 50 ECUs, electronics worth $1,100 and software cost at 13 percent of the cost of a car. Of this, 50 percent will be infotainment and 30 percent will be power train.

Impact on stakeholders

So what is the impact on the stakeholders? For OEMs, tier 1s, and semicon companies, it brings new business opportunities, and application specific solutions — common/configurable hardware differentiated by software.

It allows R&D to migrate from proprietary interfaces to open and standard-based interfaces. The impact on software developers includes use of heterogeneous processors, managing parallelism, as well as dealing with scalability, compatibility and re-usability.

Embedded software’s growing importance

Denali’s Raju Pudota focused on current trends, such as growth in UMPC (ultra mobile PCs) designs; multimedia and automotive. For hardware, it means higher integration, multiple embedded processors in one SoC, and multiple microcontrollers (MCUs) with independent functions. Most importantly, embedded software is needed to make all of this work!

He said that more software is required to run all of the IPs integrated on the chip. These can be procured from hardware IP vendors, or developed in-house or contracted to third party providers. Also, different processors require different skills and capabilities. Finally, integration and embedded OS level capabilities. Incidentally, embedded software has become a requirement on the semicon provider. However, third-party IP has been evolving slowly.

Semicon providers’ activities are manifold. These involve developing software for in-house hardware components, sourcing software from hardware IP providers, integrating various software components, and also test software offered to the system integrator.

These growing activities present its own challenges, typically: quality of software provided by hardware IP vendors, high integration time, software verification, and increased investment in software capabilities — and emergence of a new area of core competence.

What can the ecosystem do?

Given this scenario, the ecosystem has a major role to play. These include:

Ease of generation of hardware-aware software — define methods to abstract design to enable auto-generation of device drivers; define methods to auto-generate device drivers; few companies investing in this area.

Define framework/platform to integrate software — similar to on-chip interconnect; leverage mature general software development processes; and customize to specific requirements of embedded area. Finally, make software offerings open-source; leverage large independent developer community.

Ease testing of embedded software

There is also a need to ease the testing of embedded software. Some points to note: Leading semicon providers have home grown software integration and testing platforms; making use of traditional methods — hardware-software co-simulation, simulation acceleration, emulation, and FPGA testing. However, no standard methodology is said to be evolving.

Many industry solutions currently exist for hardware-software integrated testing, such as CoWare, SystemC, Mirabilis, etc. Then, there’s also simulation accelerators (parallel processing), and emulators (FPGA based).

Challenges include: huge investment in model development, high cost of ownership, the ability of third party IP provider to enable integration, and large turnaround time per test. A proper framework for the integration and testing of IPs and embedded software is the need of the hour.

Pudota added that while this is a tough challenge, it would improve time-to-market for complex SOCs, develop a third-party IP ecosystem, and enable the semicon provider to focus on core competencies.

Random Posts

Tag Cloud

3G 32nm AMD ARM China chip design DRAM DRAMeXchange EDA EDA tools embedded design embedded systems and software fabless fabs FPGAs Freescale Future Horizons global semiconductor industry global semiconductor market Hynix IC Insights India Indian semiconductor industry Indian solar/PV industry India Semiconductor Association India semiconductor market Intel iSuppli low-power design Malcolm Penn memory market mobile phones NAND Qimonda S. Janakiraman Samsung SEMI Semicon Semiconductors solar solar/PV solar cells Synopsys Taiwan TICategories

- 22nm

- 32nm

- 3G

- 3G spectrum

- 40nm

- 450mm

- 45nm

- 4G

- 65nm

- 802.11n

- 90nm

- A.Raja

- Aart De Geus

- Abhi Talwalkar

- Accellera

- Accenture

- access control

- Agilent

- Altera

- Aluminum electrolytic capacitors

- AMD

- AMS

- Analog Devices

- analog ICs

- analog mixed signal

- analog/RF

- analog/RF competency center

- Anand Chandrasekher

- Anil Gupta

- Ankush Oberai

- Apple

- Apple TV

- Applied Materials

- AqTronics

- ARIB

- ARM

- Asia

- Asiaworld Expo

- ASICs

- ASML

- ASPs

- ASSPs

- ASUS

- Atom

- Atom processor

- AUSPI

- automotive

- automotive electronics

- Bali

- bandwidth costs

- Bangalore

- Bangalore Nano 2007

- Bangalore serial blasts of July 25

- Bangkok

- Barack Obama

- Beagle Board

- Beceem

- Beijing Olympics

- Belliappa Kuttanna

- biometrics

- BIPV

- Blackberry

- Blade.org

- bloggers

- Blogging

- blogs

- board design

- Bosch Sensortec

- Brazil

- Brent Przybus

- Broadband

- Broadcom

- building integrated photovoltaics

- BV Naidu

- C++

- C-DoT

- C-to-Silicon Compiler

- Cadence

- Calpella

- carrier Ethernet

- CDG

- CDMA

- CDMA Development Group

- CDMA2000

- CDNLive

- CEA

- CEATEC

- cell phones

- Cellworks

- Charlie Hartley

- Chartered Semiconductor

- Chelsio

- Chi-Foon Chan

- Chimera

- China

- China Mobile

- China Sourcing Fair

- China Telecom

- China's IC industry

- China/Hong Kong

- Chinese semiconductor industry

- chip design

- chip designers

- Chip fabs

- chip industry

- chip makers

- chip market

- chip suppliers

- chips

- Christian Gregor Dieseldorff

- CIOL

- CIOs

- Cir-Q-Tech

- cloud computing

- CMOS

- CMOS camera modules

- CMP

- co-verification tools

- COAI

- communications

- components

- COMPUTEX

- Computex Taipei

- computing

- connectors

- consumer electronics

- Converge Market Insights

- convergence

- converter solution

- Core i7 processor

- Corporate Social Responsibility

- Cosmic Circuits

- Cowans LRA model

- CPF

- CPLD

- CPM

- cross-license dispute

- cross-licensing

- crystalline solar

- CSF

- CSR

- Cuil

- CustomSim

- CWG

- Cyclone III LS

- Cypress

- Cypress Semiconductor

- DAB

- DAB radios

- Dale Ford

- data center energy measurement

- Datang

- DAVIC

- DECT

- Deloitte

- Delphi FormFactor

- Denali

- Department of IT

- Derek Lidow

- design challenges

- design services

- design services in India

- design tools

- designers

- developers

- Dexcel Electronics Designs

- DFM

- DFT

- Diachi

- digital cameras

- digital factory

- digital president

- digital still cameras

- Digitimes

- DISCO

- Discovery 2009

- disk drive controllers

- display driver ICs

- display drivers

- displays

- DisplaySearch

- DLNA

- DLP

- Dr Farooq Abdullah

- Dr Gordon Moore

- Dr. Ashok Das

- Dr. Bobby Mitra

- Dr. Chi Foon-Chan

- Dr. Ganesh Natarajan

- Dr. Henning Wicht

- Dr. J. Gururaja

- Dr. Li Shi-he

- Dr. Madhusudan V. Atre

- Dr. Rajiv Jain

- Dr. Robert N. Castellano

- DRAM

- DRAM industry

- DRAM manufacturers

- DRAM market

- DRAMeXchange

- DRC/LVS

- driver ICs

- drug discovery

- DSOA

- DSPs

- DTG

- DTH

- DTV

- Dubai

- Dubai Circuit Design

- Durga Puja

- E Ink

- e-book semiconductors

- E-books

- e-passports

- ebooks

- EC

- EC ruling

- ECG-on-a-Chip

- Eclypse

- EDA

- EDA Consortium

- EDA industry

- EDA products

- EDA tools

- EDGE

- EEPROMs

- eInfochips

- Elcoteq

- Elections 2009

- electronic components

- electronic design engineers

- Electronic Design Trends

- electronic designers

- electronic equipment

- electronic paper display

- electronics

- electronics components

- Electronics Hardware

- Electronics industry

- electronics products

- electronics supply chain

- Electronics Weekly

- Electrophoretic Display

- element14

- Elpida

- embedded

- embedded applications

- embedded computing

- embedded design

- embedded designers

- embedded devices

- embedded Internet

- Embedded Internet devices

- embedded jobs

- embedded Linux

- embedded processor

- embedded software

- embedded systems

- embedded systems and software

- EmSys

- emulator

- Encounter

- Encounter Digital Implementation

- energy

- energy efficiency

- Enterprise

- enterprise technologies

- enterprise verification

- Enterprises

- epaper

- EPD

- Epson Toyocom

- EPSRC

- ESL

- Ethernet

- EU

- Europartners

- European Commission

- EV-DO Rev. A

- EVE

- Extreme Networks

- fab capacities

- fab policy

- fab spends

- Fab-Lite

- FabCity

- fabless

- fabless companies

- Fabless Semiconductor Association

- fabs

- Fabtech

- Farnell

- FDSOI

- femtocells

- First Solar

- fixed-mobile convergence

- flash memory

- flexible displays

- flexible substrates

- Flextronics

- FMC

- FOMA

- Forward Concepts

- foundries

- foundry semiconductor market

- FPDs

- FPGA

- FPGA Central

- FPGA design

- FPGA design software

- FPGA market

- FPGA Seek

- FPGAs

- France

- Freescale

- Freescale Technology Forum

- Frost

- FTF 2008

- Fujicon

- Fujitsu

- Fukuoka

- Fully Depleted Silicon On Insulator

- Future Horizons

- G1

- Galaxy Custom Designer

- Gartner

- Garuda

- Gary Shapiro

- GateRocket

- GE Healthcare

- Germany

- Gigabyte

- GK Pramod

- global chip market

- global DRAM market

- global EDA industry

- global MEMS market

- global semiconductor industry

- global semiconductor inventory

- global semiconductor manufacturing industry. global semiconductor industry

- Global semiconductor manufacturing utilization

- global semiconductor market

- Global silicon photonics market

- global solar industry

- Global Sources

- global telecom industry

- GlobalFoundries

- Google phone

- Gordon Moore

- GPS

- graphical programming

- graphical system design

- green data centers

- green electronics

- GSA

- GSM

- Gurdas Kamat

- Hanns Windele

- HardCopy IV ASICs

- hardware

- hardware policy

- hardware/software co-verification

- hardware/software co-verification solutions

- Harriet Green

- Harshad Deshpande

- HDDs

- HDMI

- healthcare

- High-definition

- high-K gate dielectric

- high-K metal gates

- high-level synthesis

- Hitachi

- HKMG

- HLS

- Hokoriku

- Hon Hai

- HSMC

- HSPA

- HTC

- Huawei

- hybrid car

- Hynix

- i-mode phones

- i-phones

- IBM

- IBM Research Labs

- IC ASPs

- IC industry

- IC Insights

- IC market

- IC Validator

- ICICI Ventures

- ICs

- IDC

- Idea Cellular

- IDF

- IDF Taiwan

- IDM

- iDTV

- IEF 2009

- IIM-Bangalore

- IISc. Bangalore

- IIT Bombay

- IIT Kharagpur

- IIT Madras

- IIT-Kanpur

- iMac

- IMS

- IMT

- InCyte Chip Estimator

- India

- India Inc.

- India Semiconductor Association

- India semiconductor market

- India's first plug-in hybrid car

- Indian 3G policy

- Indian aerospace and defense markets

- Indian branded memory market

- Indian EDA industry

- Indian electronics industry

- Indian embedded industry

- Indian fab story

- Indian IT industry

- Indian semicon policy

- Indian semiconductor industry

- Indian solar industry

- Indian solar/PV industry

- Indian telecom

- Indian telecom industry

- Indrion

- industrial segments

- Infineon

- Infineon Asiaworld Expo

- Infosys

- Ingo Guertler

- innovators

- InnovLite

- Inoueki

- integrated access devices

- Intel

- Intel Atom processor

- Intel Core 2 Duo

- Intel Developer Forum

- intelligent video surveillance system

- International Electronics Forum (IEF)

- Internet

- Internet radio stations

- Internet radios

- intranets

- Invensense

- IP creation

- IP re-use

- iPad

- iPDK

- iPhone

- iPhone 3G

- iPod

- IPs

- IPSec

- IPTV

- ISA

- ISA Excite

- ISA Vision Summit 2009

- ISE Design Suite 11

- ISI Calcutta

- Israel

- Istanbul

- iSuppli

- IT

- IT processes

- IT/OA

- Ittiam

- Ittiam Systems

- ITU

- ITU Telecom Asia

- iTV

- IVSS

- James Reinders

- Japan

- Japan chip industry

- Japan's microelectronics industry

- Jaswinder Ahuja

- Jayamahal

- Jayaram Pillai

- Jérémie Bouchaud

- JEM

- Jennifer Lo

- JETRO

- JMCC

- JNCASR

- Jobs in FPGAs and CPLDs

- Jon Cassell

- Jonney Shih

- Jordan Plofsky

- Joseph Sawicki

- K. Subramanya

- Karnataka

- KCR

- Kexin

- Khasim Syed Mohammed

- Kionix

- Kirk Skaugen

- Kishor Patil

- Klaus Maler

- Knowles

- Kochi

- Kodiak Networks

- Korea

- Korea Electronics Show

- KPIT Cummins

- KUKA

- Kyushu

- LabView

- LabView 8.6

- Lanco Solar

- Lara Chamness

- LAS-CDMA

- last mile problem

- Laurin Publishing

- LCD

- LCD monitor panels

- LCD monitors

- LCD panels

- LCD TVs

- LCDs

- LED driver ICs

- LED lighting devices

- LED lights

- LEDs

- Lexmark

- LG

- LG Telecom

- life sciences

- LinkAir

- Linux

- lithography

- Lo Wu

- logic IC market

- logic synthesis

- low power

- low-cost handsets

- low-power design

- LSI Corp.

- LSI Logic

- LTE

- LUT

- Mac OS

- Magma Design Automation

- Malcolm Penn

- malware

- Man Yue

- Manoj Gandhi

- manufacturing hub

- Marco Principato

- Market for key system semiconductors

- Marnello

- material devices

- McAfee

- MCMM

- MCUs

- MEAS

- Measurement Specialties

- Mediacart

- MediaTek

- mega fabs

- MelZoo

- memory

- memory fabs

- memory market

- MEMS

- MEMS accelerometers

- MEMS devices

- MEMS foundries

- MEMS gyroscopes

- MEMS industry

- MEMS oscillators

- MEMS sensors

- Memsic

- Mentor Graphics

- Messe Munchen

- metro area networks

- MHEG-5

- Michael J. Fister

- micro fuel cells

- microcontrollers

- Micron

- Micronics Japan

- microprocessors

- Microsoft

- MIDs

- MII

- MIII

- Mike Cowan

- Mike Splinter

- military

- military market

- Min-Sun Moon

- Minalogic

- mini fabs

- Ministry of Communication and IT

- mixed signal

- ML-PCBs

- MNRE

- Mobile

- Mobile application operating systems

- mobile broadband

- mobile computing

- mobile CPUs

- mobile devices

- mobile handheld devices

- mobile handsets

- mobile Internet

- mobile Internet devices

- mobile phone semiconductor market

- mobile phones

- mobile TV

- mobile VAS

- Mobile WiMAX

- Mobility

- Moblin

- modeling and photomask correction

- monitor panels

- Monolithic Power Systems

- monster fabs

- Moore’s Law

- Moorestown

- MosChip

- Moser Baer

- Moshe Handelsman

- Motorola

- Mouser

- MP3 players

- MPUs

- multi-core platforms

- multi-cores

- multicore programming

- multilayer PCBs

- Mumbaikars

- Munich

- Murata

- N.K. Goyal

- Nader Tadros

- Nam Hyung Kim

- NAND

- NAND flash

- NAND Flash memory

- Nanomanufacturing

- nanoscience

- Nanotechnology

- nanotubes

- Nanya

- National Semiconductor

- Near Field Communication

- NEC

- Neeraj Varma

- Nehalem

- Nehalem-EX

- net-tops

- netbooks

- Netscape

- nettops

- Networking

- NewEra

- next-generation data centers

- NFC

- NI

- NI. LabVIEW 8.5

- NIIT

- Nikon

- Nile

- Nimish Modi

- Ning

- Nintendo Wii

- Nios II processor

- Nishant Sarawgi

- NMI

- Nokia

- NOR

- notebook market

- notebooks

- NTT DoCoMo

- Nuance

- Numonyx

- nVidia

- NXP India

- OEM semiconductor design

- OEMs

- oil prices

- OLED

- OLED driver ICs

- OLEDs

- Open Handset Alliance

- Open Platforms

- Open Silicon

- Open Source

- OpenOffice

- Opera

- optical networking

- optos

- Outlook 2009

- OZ

- PA Semi

- packaging

- PADS 9.0

- Pagemaker

- Palm

- Panasonic

- Parallel computing

- parallel programming

- parallelism

- passives

- Patrice Hamard

- PCB industry

- PCB services

- PCBs

- PCI

- PDAs

- PDPs

- Perry LaForge

- PFI

- pharma

- Philips

- Philips Consumer Lifestyle

- Phoenix Solar

- phonons

- photonics

- Photonics in Asia

- Photonics Society of India

- photovoltaics

- physical designers

- Piketown

- Pine Trail

- place-and-route technology

- Playstation 3

- PLD

- PMPs

- PNDs

- polysilicon

- Poornima Shenoy

- power

- Power Forward Initiative

- power management

- Power MOSFETs

- Powerchip

- PowerPC

- PR firms

- Pradeep Chakraborty

- Pradeep Chakraborty's Blog

- Premier Farnell

- probe cards

- processors

- Procys

- product development ecosystem

- programmable devices

- ProMOS

- PTT

- PTT-over-cellular

- PTT/PoC

- PULLNANO

- push-to-talk

- PV

- Q-Cells

- Qimonda

- QorIQ multicore platform

- quad core

- Qualcomm

- Quark Express

- Quartus II software v8.0

- Quasar

- QuickPath

- Raghu Panicker

- Rahul Deokar

- Rajeev Madhavan

- Rajeev Mehtani

- Rajiv C. Mody

- Rajiv Jain

- Raju Pudota

- Raman Research Institute

- Ramkumar Subramanian

- Ramprasad Ananthaswamy

- Randy Lawson

- Ranga Prasad

- Ranjan Das

- Ravinder Gujral

- RCG

- REACH

- Real Player

- recession

- Red Hat

- Reliance

- Renasas

- Renesas

- renewable energy

- repairs

- Research Infrastructure

- retail

- retail POS kiosk

- Rev. A

- REVA

- RF

- RF CMOS

- RF MEMS switches

- RF surveillance

- RFMD

- Rich Beyer

- RISCs

- Riverbed

- roaming

- Robert Bosch

- RoHS

- RTL

- RV Colege of Engineering

- RVCE

- S. Janakiraman

- S. Uma Mahesh

- Sachin Pilot

- Samsung Electronics

- Samsung Semiconductor

- Sandeep Mehndiratta

- Sandisk

- Sanjay Deshmukh

- Sanyo

- SAP

- SAP BusinessObjects Explorer

- Sasken

- Sathya Prasad

- Saxony

- Science

- Scott Apeland

- Scott Grant

- screens

- SDR

- search engines

- Security

- security MCUs

- Seiko

- SEMATECH

- semconductors

- SEMI

- SEMI India

- Semico

- Semico Research

- Semicon

- semicon blogs

- semicon capex

- semicon fabs

- semiconductor

- semiconductor equipment

- semiconductor equipment industry

- semiconductor equipment market

- semiconductor industry

- Semiconductor Industry Association

- semiconductor IPs

- semiconductor jobs

- semiconductor manufacturing

- Semiconductor market for PMPs

- semiconductor materials

- semiconductor policy

- Semiconductors

- semiconductors and ICs update

- Semicondutors

- SemiconWorld

- SemIndia

- Sentaurus

- Shanghai

- Shanghai processor

- Sharp

- short-range wireless

- Shweta Dash

- Si-Quest

- SIA

- Siemens

- Signet Solar

- silicon photonics

- Silicon Sensing

- silicon wafers

- simulation

- single-chip design

- SK Telecom

- Skyway Software

- smart grid

- smart meters

- smartphones

- SMB strategies

- SMEs

- SoC

- social networking

- social networking for semicon professionals

- SoCs

- SoftJin

- software developers

- solar

- solar cells

- solar ecsystem

- solar energy ecosystem

- solar fabs

- solar manufacturers

- solar modules

- solar panels

- solar photovoltaics

- solar power products

- solar/PV

- Solar; Lux Research

- Solid polymer capacitors

- solid-state hard drives

- Sony

- Sony Ericsson

- South Korea

- Spain

- Spansion

- Spartan

- spectrum

- speech-recognition

- SPIRIT

- SPMT

- SRAM

- Sriram Peruvemba

- SSDs

- SSI

- ST

- ST Micro

- ST-Ericsson

- Stanley T. Myers

- StarOffice

- STBs

- Stefan de Haan

- Stephan de Haan

- Steve Svoboda

- STM

- STM8S

- STM8S105

- STM8S207

- STMicroelectronics

- storage

- STPI

- Strategic Marketing Associates

- Stratix IV FPGAs

- Subhash Bal

- Sun

- SunFab

- Suntech

- super fuel-efficient car

- SV Probe

- Symantec

- Synopsys

- System-in-Package (SiP) solutions

- system-level chips

- systems

- Systron Donner

- Taitronics

- Taiwan

- targeted design platforms

- Tata BP Solar

- Tata Teleservices

- TCAD

- TCS

- TD-SCDMA

- TD-SCDMA Forum

- TDD

- Technology

- Technopole

- Technoprobe

- Technovation 2008

- Tejas

- Telecom

- Telecom and IT

- telecom OEMs

- telecom operators

- telecommunications

- Telefonica

- telisma

- teliSpeech 10 Indian languages

- terror attack on Mumbai

- test and measurement

- Texas Instruments India

- Text 100

- TFPV

- TFTs

- Thailand

- The Information Network

- thin film

- thin film solar

- TI

- timing analysis

- Tipping Point

- Tom Feist

- Top 10

- top 10 embedded companies in India

- TPS62601

- traffic

- TRAI

- Transport

- Trilliant

- TSIA

- TSMC

- TV panels

- TwitterJobSearch

- TwitterJobSearch.com

- UIDAI

- UK

- UK-TI

- ultra mobile broadband

- UMB

- UMC

- unified power format

- union budget

- UPA

- Upendra Patel

- UPF

- USA

- USB

- V. Srikumar

- V.R. Venkatesh

- VC funding

- VCS2009

- VDAT 2010

- Venkatesh Valluri

- Venture GES

- verification

- Verilog

- VHDL

- Vic Mahadevan

- video roaming

- Videocon

- Vietman

- Vincent Ratford

- Virtex

- Virtex-5

- virtual instrumentation

- virtualization

- Virtuoso

- Vista

- Vivek Sharma

- VLSI

- VLSI conference

- VLSI Research

- VLSI Society of India

- voice

- vPro

- VSI

- VTI

- VTU

- W-CDMA

- wafer fabs

- wafer processing equipment

- Walden C. Rhines

- WAP

- WDS

- Web 2.0

- Webdesign International Festival

- WEEE

- West Bengal

- Wi-Fi

- Widgetbox

- widgets

- WIF 2008

- WIF 2010

- WiLL

- Will Strauss

- WiMAX

- WinCE

- Wind River

- wind solutions

- Wipro

- Wipro Technologies

- wired communications

- Wireless

- wireless devices

- wireless handsets

- Wireless USB

- Wireless Week

- wireless/DSP bulletin

- WirelessHART

- wireline

- WiTECK

- Workhound

- World Cup Cricket 2011

- WSTS

- WUSB

- X-Con

- Xeon 5500

- Xilinx

- yield management

- YieldManager

- Yindusoft

- Yole

- Yole Developpement

- Yukon

- Z-RAM

- ZeBu

- ZeBu-Server

- Zetex

- ZigBee

- ZTE

Blogroll

Archives

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- September 2009

- August 2009

- July 2009

- June 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- November 2008

- October 2008

- September 2008

- August 2008

- July 2008

- June 2008

- May 2008

- April 2008

- March 2008

- January 2008

- December 2007

- November 2007

- October 2007

- September 2007

- August 2007

- July 2007

- June 2007

- May 2007

- April 2007

- March 2007