Archive

Round-up 2010: Best of solar photovoltaics

Solar photovoltaics (PV) constantly reminds me of the early days of the telecom industry. Perhaps, the similarity lies in practically anyone and everyone wants to enter the solar/PV industry as well, just like it happened in telecom — before the industry consolidation started to happen.

In India, a lot more talk has happened since the Jawaharlal Nehru National Solar Mission (JN-NSM) was unveiled. With 2010 now drawing to an end, here’s presenting the top posts for solar PV from the year that is about to leave all of us!

Want to enter solar off-grid business? Build your own solar LED lanterns and emergency lights! — This was a smashing superhit! So many folks have accessed this post and quite a few commented! Definitely, my no. 1 post for the year and among my top 10 posts for 2010!

Union budget 2010: Solar, UIDs all the way!

NI DAQ workshop: Sun tracker suitable for Indian (and global) solar/PV industry

India to miss NSM target? No, it’s likely a mistake (in reporting)! — The faux pas of the year! 😉

SEMI India benchmarks India’s NSM on global FIT best practices — Goes on to show why SEMI continues to be a top notch industry association!

RoseStreet Labs develops breakthrough multiband solar cell technology! — I enjoyed writing this post a lot!

Solar PV heats up in India — NVVN signs MoU with 16 developers; new guidelines for solar projects — First clear signs that India is indeed hot, as a solar market.

Unique solution required for grid-tie inverters in India!

Solarcon India 2010: Timely implementation of phase 1 critical to success of JN-NSM

Need to develop indigenous manufacturing capacity in solar: Deepak Gupta

Is there a case for polysilicon manufacturing in India?

India has bright future in solar PV, other RE: Stan Meyers, SEMI

Pressing need to address solar project financing in India: D. Majumdar, IREDA

TÜV Rheinland opens South Asia’s largest PV testing lab in Bangalore

Need to look at smart grid standards from an Indian context: Venkat Rajaraman, Su-Kam

Bluetooth set as short range wireless standard for smart energy! — This should be interesting, as and when it happens!

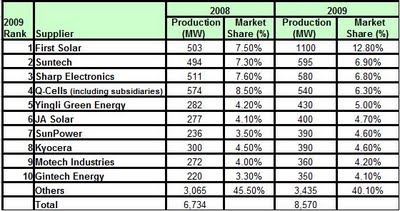

Top 15 producers of c-Si and thin film solar PV modules, and outlook 2011

There’s more to come in the new year, now that NVVN has released a list of projects under the JN-NSM. I am more keen to see how JN-NSM takes off in the new year, and am sure, so are you!

Here’s wishing everyone a very happy, joyous and prosperous 2011! 🙂

Top 15 producers of c-Si and thin film solar PV modules, and outlook 2011

I am extremely grateful to Stefan de Haan, senior analyst, Photovoltaics, iSuppli Corp., for sharing with me the top 15 global producers of c-Si and thin film solar photovoltaic (PV) modules, respectively during Q3 2010.

First, the top 15 global crystalline module producers (see Fig. 1) — who are the standout performers and why?

He said: “It is still the Chinese integrated suppliers, above all Trina and Yingli. They benefit from a highly competitive cost structure. However, this need not be the most successful business model in future. With increasing cell and module efficiencies, and an increasing need for full automization, European and Japanese companies may gain ground again.”

Now, on to the top 15 global thin film module producers (see Fig. 2)– who are the standout performers here!

de Haan added: “Still, it is First Solar, the company with lowest production cost in the industry and the biggest module producer. CIGS is upcoming, in particular. Solar Frontier also has to be watched.”

Global PV installations to grow significantly in 2011

It is said that global PV installation will likely witness moderate growth in 2011, and that, concerns of oversupply remain. de Haan agrees only partly.

He said: “Global PV installations will again grow significantly in 2011 (2010: 16 GW and 2011: 22.2 GW). Oversupply will not be dramatic in 2011, but in 2012 and 2013.”

Further, if the pressure from decreasing solar cell price continues to increase, will solar cell makers be forced to reduce prices of wafers and poly-Si to reflect costs? According to Stefan de Haan, prices will drop across the entire solar value chain in 2011! Read more…

Solar PV likely showstopper at electronica India 2010 and productronica India 2010

For those interested, since its debut in 2009, this show has been split into two sections – productronica India — devoted to production technologies, SMT and EMS/contract manufacturers, PCB, solar and PV, laser, etc., and electronica India – focused on components, semiconductors, assemblies, LEDs and materials.This year, there are going to be three added attractions or special exhibit areas, namely:

* Solar pavilion.

* LED pavilion.

* Laser pavilion.

Solar PV main attraction

A report on the ‘Solar PV Industry 2010: Contemporary Scenario and Emerging Trends’ released by the India Semiconductor Association (ISA) with the support of the Office of the Principal Scientific Advisor (PSA), lays out the strengths and challenges of the Indian solar PV market:

* Even though the industry operates at a smaller scale as compared to other solar PV producing nations, production in India is very cost effective as compared to global standards.

* With Government initiatives such as the SIPS scheme and JN-NSM in place to promote application of solar PV in domestic market, the Indian solar PV industry is likely to gain further edge over other solar PV producing nations.

* There is no manufacturing base in India for the basic raw material, that is, silicon wafers.

* Over the last five years, China has emerged as the largest producer of solar cells in the world. The country currently has about 2,500 MW of production capacity for solar PV as compared to India’s 400 MW. Taiwan, with annual capacity of 800 MW, is also emerging as a major threat to the Indian industry.

* Price reduction is another major challenge for the industry as this would have greatly impact the future growth of the market.

The recently concluded Solarcon India 2010 threw up several interesting points as well. Industry observers agreed that the timely implementation of phase 1 of the historic Jawaharlal Nehru National Solar Mission (JN-NSM) is going to be critical for the success of this Mission.

The MNRE stressed on the need to develop an indigenous solar PV manufacturing capacity in solar, and build a service infrastructure. Strong emphasis is also being placed on R&D, and quite rightly. Notably, the Indian government is working toward tackling issues involved with project financing as well.

All the right steps and noises are currently being taken and made in the Indian solar PV industry. If these weren’t enough, the TÜV Rheinland recently opened South Asia’s largest PV testing lab in Bangalore!

This year, an exhibitor forum on PV and solar will also take place at the Solar PV pavilion during electronica India 2010 and productronica India 2010.

Read more…

TÜV Rheinland opens South Asia's largest PV testing lab in Bangalore

Just last week, Deepak Gupta, secretary, MNRE, had mentioned during his valedictory address at Solarcon India 2010 that an international lab was due to start a facility in Bangalore, and here you go! But first, a bit on TÜV Rheinland.

TÜV Rheinland has the expertise of testing PV modules, having been in the solar business for over 30 years. It has a market share over 70 percent, and has seven PV labs spread across Germany, China, Taiwan, the US, Japan (two labs), and now, India. Its testing focus is on safety, efficiency, quality and durability of solar systems.

According to the TÜV Rheinland official, the total global investment in solar PV reached a record $40 billion in 2009. The PV cells production capacity is likely to exceed 33GW in 2011. Most importantly, 78 percent of manufacturers will be located in Asia. Further, the installed capacity of global solar panels is likely to reach 33.4 thousand MW by 2015.

Business prospects in India

TÜV Rheinland obviously has been closely following the Indian solar PV market. India boasts of over 250 clear sunny days in year. Also, India’s solar potential is estimated at 600 TW per year. The PV industry output between 2002 and 2007 was said to 335 MW, with an export rate of 75 percent.

Coming to well known Jawaharlal Nehru National Solar Mission (JN-NSM), the Indian solar PV industry is estimated to grow to 100 GW by 2030. Also, 5 percent of the total power plant area will be used for PV power plants. The Indian government is promoting roof top solar generation.

TÜV Rheinland’s test laboratory in Electronics City, Bangalore, is spread over an area of 20,000sqft., including 5,000sqft. outside exposure testing area. It has invested close to $3 million in setting up the lab, thereby indicating a very deep interest in developing the Indian solar PV industry.

This PV test lab in Bangalore also happens to be India’s first and South Asia’s largest such facility. It has some unique facilities such as five climatic chambers and two sun simulators. With the inauguration of this facility, the availability of local testing and certification will now plug a key gap for the Indian industry.

TÜV Rheinland is offering the following PV services in India – PV module testing, PV module certification, PV power plants, conventional power projects, welding and non-destructive testing, installations, material tests and third party inspections. For the statistical minded, 70 percent of PV modules go through one of the TUV Rheinland labs worldwide.

The group’s global management is well focused on the Indian market and this PV test lab is a reiteration of an ongoing, long-term commitment to India.

Friedrich Hecker, CEO, TÜV Rheinland AG, said: “With the ambitious Jawaharlal Nehru National Solar Mission being operationalized, India is poised to take a huge leap in solar/PV. Module manufacturing, a key component of the chain, is largely domestically manufactured and offers a great export potential as well.

“The setting up of the PV lab by us today in Bangalore not only addresses the lack of such a facility in India but actually enables Indian module manufacturers to eye markets beyond India. India has always been a key strategic market for the group and all our different business units and this marks another step forward in that commitment.”

Andreas Höfer, chief regional officer, TÜV Rheinland (India, Middle East and Africa), said, “With abundant sunshine and high quality of radiation levels combined with focus on both grid and off grid applications, there is every possibility that India will be the market to watch out for in the region. We see a lot of overseas players investing here and setting up facilities or licensing technology for local players to manufacture with. In that way, both our entry and the setting up of this lab is timed well.”

Enrico Rühle, MD, TÜV Rheinland India, added: ”The Indian PV lab will be tightly interlinked to the other six laboratories across the world and will employ over 200 experts across functions. The lab which has facilities unheard of in the region like climate chambers and sun simulators will reduce the time for testing for Indian manufacturers.”

TÜV Rheinland India is part of the TÜV Rheinland Group, a leading provider of technical services worldwide. Read more…

Solarcon India 2010: Timely implementation of phase 1 critical to success of JN-NSM

Strong emphasis is now being placed on research and development, and rightly so. The Indian government is also working toward tackling issues involved with project financing.

Let’s take a look at what the various dignitaries from Central and State governments, EPIA and SEMI, had to say at Solarcon 2010. Please bear with me as this is quite a long post!

India needs to develop research facilities

Delivering his address at the inaugural function of Solarcon 2010, Dr. Farooq Abdullah, Hon’ble Union Minister for New and Renewable Energy highlighted that JN-NSM has been the vision of Dr. Manmohan Singh, the Indian Prime Minster. Phase 1 is now underway — a target of 1,000 MW, with 500MW for solar PV and 500MW for solar thermal.

Addressing the Indian solar PV industry, Dr. Abdullah stressed: “India should develop its technology right here! Don’t import third rate technology!” He quipped, “Sastaa roye bar bar, mehengaa roye ek bar!” That is, it is better to buy expensive and quality technology rather than banking on cheap technology.

“Your technology has to work for 25 years! You must have your own research centers. Research is one of the goals of the NSM. You have to do your own research. You are going to the market, not only for India, but also for a unified world,” he added.

The Minister remarked that by simply adding solar water heaters in several hotels had reduced their electricity bills by half. He added: “We want to encourage many players. We want true players!” Addressing the solar thermal and PV debate, he said: “When we started, we put 60:40 for thermal and PV. We changed that to 50:50.” There may be a need to go down further. “Buy the best technology, don’t buy cheap,” the Minister insisted.

He added that many states had missed the boat in phase 1 of the JN-NSM. Some examples include Bihar and Kerala. However, there is every likelihood that they will get included in phase 2 of the JN-NSM. “Look at the amount of fossil fuels we are importing at the cost of dollars and the country’s health. Just look at the savings we can do for the nation if we can develop solar technology,” added Dr. Abdullah.

Solarcon India 2010 kicks off in Hyderabad!

Honourable Union Minister for New and Renewable Energy, Dr Farooq Abdullah, along with Honourable Chief Minister of Andhra Pradesh, K. Rosaiah, and Honourable Union Minister for Urban Development, Jaipal Reddy, inaugurating Solarcon India 2010.

Solarcon India 2010, the second edition of India’s largest solar-energy-focused event organized by SEMI India, the premier trade body of the Indian solar/PV industry, kicked off at HICC, Hyderabad today.

Honourable Union Minister for New and Renewable Energy, Dr Farooq Abdullah, inaugurated the three day exposition and conference. Honourable Chief Minister of Andhra Pradesh, K. Rosaiah presided over the event. Honourable Union Minister for Urban Development, Jaipal Reddy, was the Guest of Honour.

The conference keynote was delivered by Dr Winfried Hoffmann, President, European Photovoltaic Industry Association.

India’s first solar industry directory, published by SEMI India was released on the occasion.

More details later… am still at the conference! 😉

Dr. Robert Castellano on how to make solar a ‘hot’ sector again – 2

Dr. Robert N. Castellano, president, The Information Network

Friends, this is the concluding part of my conversation with Dr. Robert N. Castellano, president of The Information Network, based in New Tripoli, USA.

The question of adding new, additional solar capacity will always arise. Is it the certain that no new additional capacity will be brought on board in 2009?

Dr. Castellano noted: “Actually I said 2010. Solar manufacturers are already losing money this year and the capacity utilization is 27.9 percent. Also, the days of inventory are currently 122, up from 71 days in 2008. If they continue to add new capacity, things will only worsen, exasperating the recession.”

What lessons for India?

Turning our attention to India, which has lately been witnessing a lot of talks of building new capacity. According to Dr. Castellano, now is a good time to talk, as a plant will take at least a year to get into full production. By that time, prices should be stabilized and increase.

What then are the lessons to learn from all of this for the Indian solar PV industry?

He added: “What has to be weighed is the cost of making the solar panels in India versus buying the outside the country. It can take several years for a plant to be profitable. If the venture was established from money from India’s government through subsidies, it can lessen the impact of potential losses, while the plants ramp and selling prices move up to a level where production becomes profitable.”

I hope this valuable piece of advice is noted by the existing players or those looking to entering the solar photovoltaics segment in India.

Bring solar production cost per watt down

Dr. Castellano had mentioned about First Solar bringing production costs down to $0.93 per watt. How many of the others are capable of matching or bettering this?

He said, for that matter, Oerlikon, expects that its lines will deliver a cost of $0.70 cents per watt by the end of 2010 and has achieved an initial conversion efficiency of 11 percent, which comes out to about 9.5 percent of stabilized efficiency.

How can manufacturers differentiate their solar products?

Another query has been, how should solar manufacturers differentiate their products and how can they do it cheaply?

Certainly, there are new avenues of manufacturing, such as CdTe from First Solar, CIGS from half a dozen manufacturers, multi-junction cells from companies such as Uni-Solar, and building integrated photovoltaics (BIPV) from an increasing number of manufacturers, advised Dr. Castellano.

He said: “These technologies differentiate the companies’ products, but the proportion of wattage manufactured, while growing, is small compared to the majority of solar panels sold using traditional methods of production, i.e., a thin film on a glass substrate.

“Long life and low cost of ownership are of paramount importance if solar is to grow, particularly, if there is to be a large acceptance at the residential level. Manufacturing can introduce defects in solar cells that can result in low electron mobility (EM), electron traps and photo-degradation from UV light. These issues affect the efficiency and lifetime of solar cells and the importance of measuring electron mobility at the wafer and cell stage.

“The lifetime of minority carriers has been widely identified to be the key material parameter determining the conversion efficiency of pn-junctions in silicon solar cells. Defects in the crystal lattice reduce the charge carrier lifetime and thus limit the performance of the solar cells. Another major efficiency loss is due to impurities in the cell. These can be foreign atoms or molecules in the crystal lattice (including the dopant atoms), and provide sites where electrons and holes can recombine, thereby reducing the number of charged particles available to create an electrical current.

“Lehighton Electronics (Lehighton, PA) is an example of a company that has developed a variety of tools to test and measure solar wafers. One tool can measure sheet resistance and resistivity to see if there is any subsurface damage. Another system can measure minority carrier lifetimes, while a third model can find traps in solar wafers.” Read more…

Indian government, solar industry interact on MNRE's solar PV program

Poornima Shenoy of ISA welcoming delegates. On the dias (L-R): Dr. B.M.S. Bist, Ms Gauri Singh, B.V. Naidu, Debashish Majumdar and Rajiv Jain

To promote this program, the MNRE organized a one-day seminar today, in New Delhi, along with the India Semiconductor Association (ISA), and the Indian Renewable Energy Development Agency Ltd (IREDA), to share the modalities for the implementation of the program with the concerned stakeholders such as manufacturers of solar PV modules and equipment, system integrators, service providers, consultants, banks and financial institutions, and reputed NGOs. A government-industry interaction on the MNRE’s program was also intiated during the event.

Huge opportunity in off-grid applications

Ms Gauri Singh, IAS, joint secretary, MNRE said that the purpose of this interaction between the government and the industry is to give a loud and clear message to Indian solar photovoltaics industry that “we would like to work with you as partners.”

She added: “A large portion of the solar mission target will come from grid connected solar power. However, the off-grid opportunity is also huge. We have tried to open up our policy slightly — and take the whole process forward by taking inputs from you — and open up the policy for suggestions. One part of the scenario is — we already have large manufacturers who can provide us solar modules. The other part — is our policy encouraging innovation.

“Now, the time is ripe where we can do only the broad technical specifications, etc., but leave the innovation and configuration of the off-grid solutions to the industry, and make it an enabling flavor.” She also called for a need to put out a third party monitoring system.

She further added that the MNRE was also working to see whether it could get the IREDA into a refinance operation with banks.

There are schemes in place, where if anyone wants to work with a bank, a lot of incentives are available to the banks. Now, the ministry would like to see incentives being given to the manufacturers.

Industry-government interaction step in right direction

Earlier, welcoming the delegates, Poornima Shenoy, president, ISA, stressed on the very strong partnership between the MNRE and the ISA. She added that this workshop was a first in a series of such workshops that will be held across the country. She requested the delegates to add as much value as possible to this edition, adding, “We look forward to your feedback, so that we can improve on our future programs.”

Incidentally, the current installed capacity of solar PV is said to be over 400-500MW, but about 90 percent of that capacity is exported. As a case, in Germany, 4 percent of the overall power generation capacity has been generated out of solar. A lot of emphasis on solar PV also been happening in the USA and Chima.

The ISA has already created the roadmap for the FabCity in Hyderabad. It is also organizing a solar conference in Hyderabad this November.

Solar to assure green technology in India

Dr B.M.S. Bist, Advisor, MNRE, said that solar PV is going to play a big role in assuring green technology in the country. A date of Nov. 14 has been set for Solar Mission Program, as already mentioned.

A view of the government-industry interaction. (L-R): D. Majumdar, Dr. B.M.S. Bist, Dr. A. Raza, B.V. Rao and AK Varshney.

Massive potential for solar PV in India

Addressing the delegates, Debashish Majumdar, chairman and managing director, IREDA, said the reason for the gathering today was very clear — what exists on the MNRE website is potential for renewable energy. However, it does not really highlight the potential for solar PV, which is massive!

He added: “When solar PV started about 15 years ago in India, we had small manufacturers starting in garages, etc., and who have now grown to become very large companies. It gives us a lot of hope that things can be done very well here as well. Any new technology, to begin with, is expensive. Therefore, it is the prerogative of the rich to adopt it. We all hope that we will have the volumes and the technologies that can be replicated in India.

“We look at solar from two aspects — off-grid and on-grid. We would like to see what kind of demand can we convert in the off-grid applications. In the subsequent session, we will see the steps that the ministry has taken. The policy has been made keeping the best interests of the industry. We would like to get your feedback and see how best to get the market going.”

This is indeed, an honest attempt on part of the MNRE to work closely with the industry. Hopefully, everything will go well, following this interaction as it will sow the right seeds toward reaping a full harvest — in shape of achieving the very ambitious target of the government of India’s national solar mission plan!

There were presentations on the following topics as well:

* Details of the solar PV off-grid program (rooftop systems) — Dr. AK Varshney, MNRE

* Details of the solar PV off-grid program (other applications) — Dr. A. Raza, MNRE

* Financing of IREDA schemes for solar — BV Rao, IREDA

These presentations were followed by a marathon discussion between the MNRE and IREDA officials on behalf of the government of India and the members of the Indian solar photovoltaics industry.

Dr. Robert Castellano on how to make solar a 'hot' sector again – 1

Dr. Robert N. Castellano, president, The Information Network

Last week, I was very fortunate enough to be able to get into a conversation with Dr. Robert N. Castellano, president of The Information Network, based in New Tripoli, USA. It all started with a column, which he writes regularly in “The Street.” One of the recent colums of Dr. Castellano touched upon –- What could make solar hot again?

How to rectify the solar cell oversupply?

He said: “The problem will rectify itself when demand catches up with supply, which will take several years. Until then, suppliers are faced with lower prices and margins. I was the first to point out on March 5 2008, in my blog on Seeking Alpha in an article entitled “Contradictions in the Solar Industry” that “The solar industry is faced with a huge oversupply of solar panels planned for production in 2008, but no one seems to notice… or care. Shares in many solar companies such as Evergreen Solar), First Solar SunPower, and Suntech Power have surged with the booming solar market.”

Six reasons for cloudy solar skies

1. With oil at $60 a barrel, who cares about alternative energy? It is a short sighted view, but with the credit market crunch, who can get a loan to build solar plants anyway?”

Have companies been overlooking inventory problems?

Dr. Castellano said: “The solar companies were benefiting from the low price of polysilicon as a result of excess inventory in that sector. They were renegotiating contract prices with the poly suppliers and dropping prices. With money in place, they continued to build capacity well into 2009. All the factors discussed above took everyone by surprise (witness the stock market crash) and the recession has lasted much longer than initially forecast.

Where does this place a-Si solar cell makers?

“The issue is the economics in a solar farm where they are installed. The installation price is the same as a polycrystalline panel. Since the efficiency is lower and it takes more panels to reach the same wattage as polycrystalline, it also takes more hook-ups and frames during installation.

“If the panels move, there is another factor in the motors to move them. However, the production cost is lower than the polycrystalline panels. Oerlikon, expects its lines will deliver a cost of 70 cents per watt by the end of 2010 and has achieved an initial conversion efficiency of 11 percent, which comes out to about 9.5 percent of stabilized efficiency.”

Crystalline vs. thin film capacity

Dr. Castellano said: “Until last year, Germany had been the world’s largest solar market thanks to its feed-in tariffs, which require utilities to buy all the solar energy produced at premium, government-set prices. As a result, analysts now expect Germany, which doesn’t have an annual cap like the one in Spain, to become the biggest market again in 2009.Germany installed 1.35 gigawatts of solar energy systems in 2008, and it could add another 1.5 gigawatts in 2009.

“Spain took the lead last year, but the government has since reduced the subsidies and capped the amount of energy that could be sold under the subsidy program. The financial market crisis has made it difficult for developers to line up financing for solar power projects. Spain, which added a few gigawatts of solar in 2008 alone, now has a 500-megawatt cap for 2009. All of these forces have led to an oversupply of silicon panels.

“As governments — Germany and Spain were a driving force – in the solar industry’s run-up, they were a factor in the downturn. Once the recession is over and liquidity returns, they will mitigate the overcapacity, particularly as prices are so low and there is pent-up demand for new installations.”

Impact of Q4 on overall prices and industry

Dr. Castellano said that silicon used to sell for more than $300 per kilogram on the spot market and $150 per kilogram for long-term contracts a few years ago. Silicon prices have since fallen significantly over the past year. In fact, the long-term contract price has dropped about 50 percent, close to the spot market price of $67 per kilogram, or about $0.50 per watt.

“Polysilicon panels are selling at $2.25 to $2.50 per watt from $4.17 in Q2 2008. We expect prices to decline further throughout the remainder of the year,” he noted.